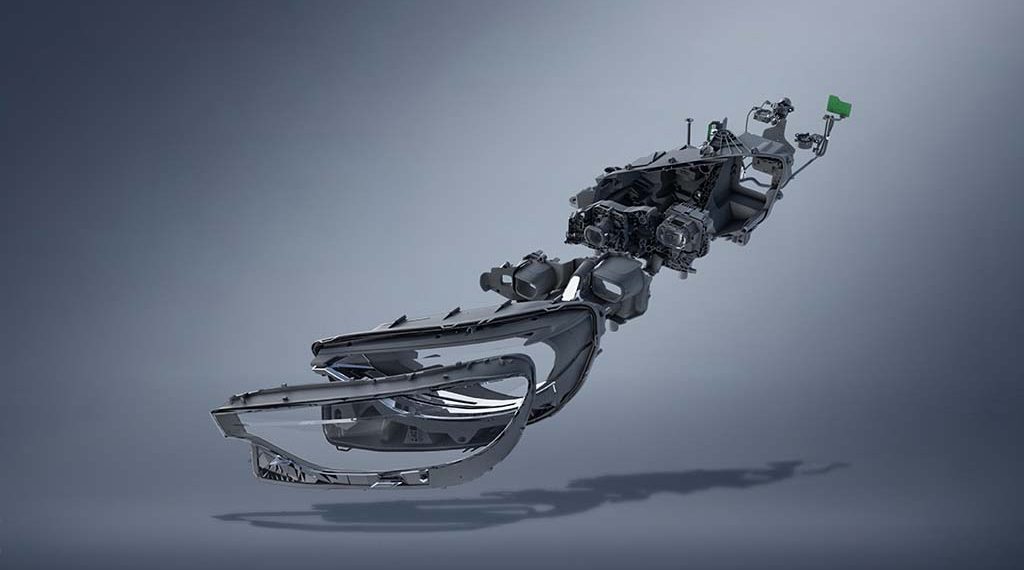

Mercedes-Benz is pushing the boundaries of sustainability with its Mission X initiative. The company is making headlights repairable for the first time. Unlike current models, which use glue to hold parts together, the new headlights will rely on screws. This change will allow technicians to replace individual components instead of the entire headlight unit.

How Mercedes is Making Headlights More Sustainable

Mercedes’ new design lets technicians easily unscrew and replace damaged parts. For example, a cracked lens can be swapped out, saving time and money. This new approach reduces waste and lowers repair costs. As adaptive LED headlights can be very expensive, this simpler, more affordable repair option will help car owners.

The new screw design also benefits the environment. It makes recycling easier because individual parts can be separated and reused. Avoiding the need to replace the entire headlight assembly lowers the car’s overall carbon footprint.

Mission X: Mercedes-Benz’s Comprehensive Sustainability Effort

The Mission X initiative extends beyond repairable headlights. Mercedes is committed to using more recycled materials in its vehicles. The company uses fiberglass-reinforced polyamide from old airbags for parts like engine mounts and valve housings. Additionally, recycled plastics from scrapped vehicles are now used for underbody cladding on new models.

Mercedes is also experimenting with recycled plastic from old tires. This material helps create artificial leather, which is more durable than traditional leather. The company is also using fibers from tires in vibration dampers and recycled PET for door pockets, reducing weight by 40 percent.

The Environmental Impact of Repairable Headlights

Repairable headlights represent a step forward in reducing environmental impact. While people often focus on exhaust emissions, a car’s environmental effect starts long before it hits the road. By using recycled materials, Mercedes is cutting down on the need for raw materials, which helps reduce overall pollution.

The company’s approach to using secondary raw materials contributes to a circular economy. This method lowers pollution by making the most of existing materials. It shows that sustainable car production doesn’t have to compromise on performance or luxury.